Synthetic fuels explained

There is a lot of talk about renewable synthetic fuels recently. They are generally seen as a technology that will play an important role to reach net zero in the transportation sector. Terms like “biofuel”, “synfuel”, and “e-fuel” are often used interchangeably. But there are important differences between the various types of synthetic fuels regarding their production, scalability, and sustainability. So let’s shed light into the seemingly complicated world of synthetic fuels and learn about the basics of synthetic fuel production. It’s not all that complicated – we promise!

What are synthetic fuels?

Synthetic fuels are liquid fuels that basically have the same properties as fossil fuels but are produced artificially. They can be used in the same way as fossil fuels are used all around the world. For example, it is possible to produce synthetic jet fuel, diesel, or gasoline for conventional planes, ships, trucks, and cars. The main difference between fossil and synthetic fuels is how they are produced: fossil fuels are formed over millions of years underground from organic matter that is turned into coal, natural gas, or oil. Synthetic fuels are produced by mimicking these natural processes using renewable resources.

How are renewable synthetic fuels produced?

To understand the production of renewable synthetic fuels, you have to understand what fossil fuels are made of: put simply, they are made of chains of the elements hydrogen (H) and carbon (C). Or in other words, they consist of hundreds of different hydrocarbon molecules.

The key to producing synthetic fuels is syngas, a mixture of hydrogen (H) and carbon monoxide (CO). Think of syngas as a brick. Once you have bricks, you can build any shape of house. Syngas is the universal brick you need to produce any type of liquid hydrocarbon fuel, such as jet fuel, diesel, or gasoline. Turning syngas into fuel is an established industrial process that has been applied on a large scale for decades, using coal and natural gas as feedstocks, which is of course not sustainable. So that’s exactly where the challenge lies: producing syngas sustainably. The production of syngas requires a large amount of energy. To produce it in a sustainable way, this energy needs to come from a renewable resource, such as biomass, solar, wind, or hydro.

What types of renewable synthetic fuels are there?

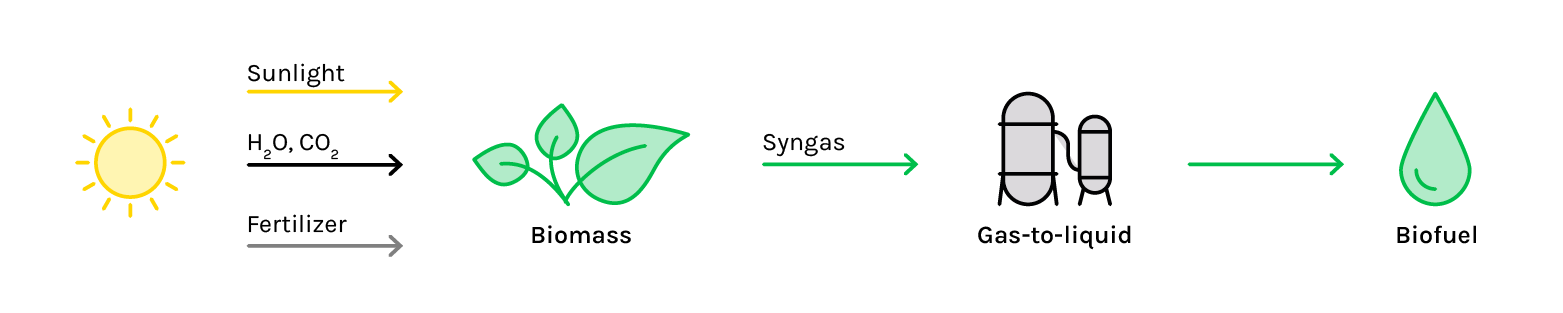

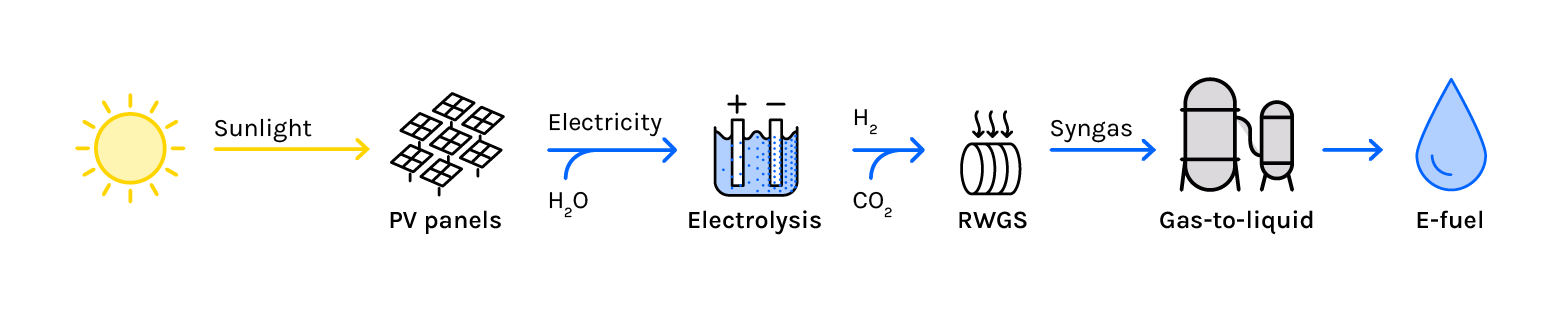

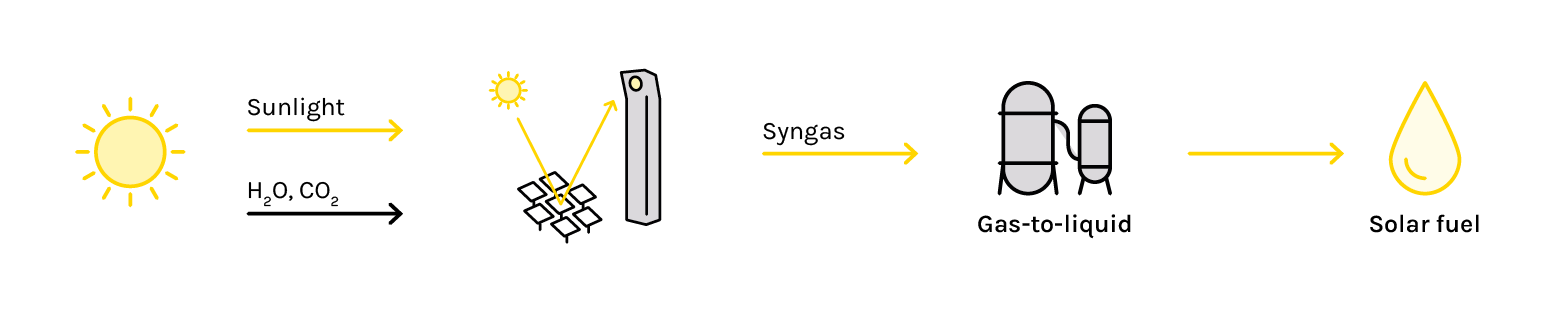

To date, three methods for the production of renewable syngas, and consequently climate-friendly synthetic fuels are known: biofuels, which are produced from biomass, e-fuels, which are produced with renewable electricity, and solar fuels, which are produced with solar heat. All three methods mainly go through syngas, a mixture of hydrogen and carbon monoxide. The syngas is subsequently turned into liquid fuels via industrial gas-to-liquid processes. That’s why these three methods are sometimes also referred to as “Biomass-to-Liquid”, “Power-to-Liquid”, and “Sun-to-Liquid” respectively.

Biomass-to-Liquid produces biofuels

Power-to-Liquid produces e-fuels

Sun-to-Liquid produces solar fuels

Solar fuels are produced from solar heat that drives a thermochemical reactor. In the reactor, carbon dioxide and water are converted into syngas. Just like e-fuels, solar fuels are not yet available on the market. Sunny regions offer ideal conditions for the production of solar fuels, in particular deserts and semi-arid regions with high solar radiation. The solar heat generated during the day can be stored by inexpensive thermal energy storage to enable round-the-clock production of fuels. Storage makes solar fuel plants self-sufficient and independent from any grid, giving them the potential to be scaled quickly and broadly.

Where can synthetic fuels be used?

Synthetic fuels are fully compatible with the existing global fuel infrastructure. They can be used in conventional internal combustion engines and jet engines, meaning that regular cars, planes, and ships can be fueled up with synthetic fuels without being changed or refitted. Furthermore, they can use the established fuel infrastructure for storage and distribution.

Renewable synthetic fuels are generally seen as a solution to decarbonize in particular those transportation sectors that cannot be electrified. Long-distance transportation needs energy carriers with a very high energy density and, therefore, will continue to rely on liquid fuels as they contain 60 to 100 times more energy per mass than lithium-ion batteries. For long-distance aviation, batteries are simply too heavy and bulky. Therefore, the aviation industry counts on renewable synthetic fuels – which they call Sustainable Aviation Fuels (SAF) – to reach net zero in the future.

What type of synthetic fuel does Synhelion produce?

Synhelion produces solar fuels. We have based our technology on sunlight because the sun is the most abundant and most distributed renewable energy source there is. We minimize the number of energy conversion steps by using the solar heat directly to turn carbon dioxide into fuel, thus maximizing fuel production efficiency. Working with solar heat has another huge advantage: thermal energy storage is much cheaper and environmentally friendlier than battery storage. Thanks to our proprietary thermal energy storage, we can produce fuels around the clock, unlocking synthetic fuel production at an unprecedented low price that is competitive with fossil fuels and more economical than other synthetic fuel technologies.

Learn more about Synhelion’s solar fuels.