Global demand for both oil and gas is set to peak by 2030, according to the latest International Energy Agency (IEA) projections. If governments act to reach Net Zero emissions by mid-century, which is necessary to keep the goal of limiting global warming to 1.5 °C within reach, oil and gas use would decline by more than 75% by 2050.

Yet the oil and gas sector which provides more than half of global energy supply currently account for just 1% of clean energy investment globally. “The oil and gas industry is facing a moment of truth,” IEA Executive Director Fatih Birol, said duringt COP28 in Dubai in December. “With the world suffering the impacts of a worsening climate crisis, continuing with business as usual is neither socially nor environmentally responsible,” he said. “Oil and gas producers around the world need to make profound decisions about their future place in the global energy sector. The industry needs to commit to genuinely helping the world meet its energy needs and climate goals – which means letting go of the illusion that implausibly large amounts of carbon capture are the solution.”

Synhelion, a Swiss scale-up which has developed a breakthrough method to produce renewable synthetic fuel from CO2, water, and sunlight, is proposing a way forward. It wants to license its technology to gas and oil companies and have them become the future owners and operators of green fuel production plants. “There is a huge technology overlap and spending several billion per plant is nothing new for oil and gas and the energy sector,” says Philipp Furler, CEO and Founder of Synhelion, which was recently named a Global Innovator by The World Economic Forum. “Oil and gas companies could be the future owners and operators of our plants but so could other players. We are open and willing to provide our technology to industry partners.”

Synhelion is a member of the EU SUN-to-Liquid II research project which was launched in November and aims to demonstrate the scalability and high efficiency of producing sustainable synthetic fuel from Co2, water and sunlight. The consortium, which also includes the German Aerospace Center, Spain’s IMEDEA Energy Institute, German aviation think tank Bauhaus Luftfahrt, industrial gas supplier HyGear and science and business consultancy L-up, aims to bridge the gap between research and industrial applications in high temperature sunlight-driven chemistry.

“We want to develop solutions that will create global impact,” says Furler.

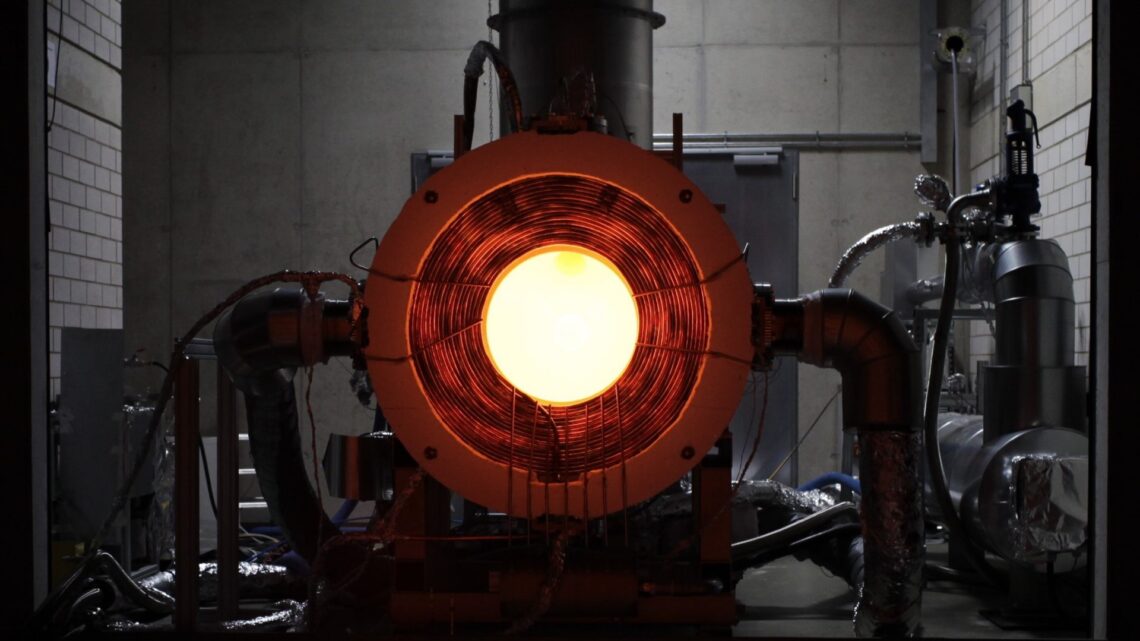

As a leader in high temperature solar chemistry Synhelion, a spin-off of ETH, holds exclusive licenses to commercialize the Sun-to-Liquid process. Within the SUN-to-LIQUID II project Synhelion and its partners develop a technology that uses concentrate solar radiation to drive a two-step redox process to convert Co2 and water into syngas. This process has the potential to produce renewable synthetic fuels at high efficiency. The process uses less energy than more mature power-to-liquid technologies that convert hydrogen into syngas and is more economical because it is 10x to 20x cheaper to store heat than electricity.

Synhelion evolved from ETH Zurich in 2016 to decarbonize transportation. The process it developed for green fuels works like this: when the sun is shining solar radiation is reflected by a mirror field, concentrated onto a receive and converted into high-temperature process heat. The generated head is fed to a thermochemical reactor that produces synthesis gas. This is them processed into fuels by standard gas-to-liquids technology such as the Fischer-Tropsch process. The set-up also includes thermal energy stage, which enables fuel production around the clock. The end-product is solar kerosene, diesel or gasoline that can be burned in standard engines.

The Swiss scale-up is currently building DAWN, the world’s first industrial-scale solar fuel plant in Julich, Germany, which is scheduled to open in June of this year. DAWN combines proprietary concentrated solar technology with industrial reforming technology to convert biogenic methane, C02 and water into syngas, which is then turned into jet fuel, diesel, and gasoline. This solar reforming process combines both established and new technologies, allowing for a faster market entry of carbon-neutral solar fuels. Synhelion’s future plants will be able to produce solar fuels directly from solar energy, CO2, and water.

A plant in Spain is due to open in 2026. The aim is to have that plant produce 1.25 million liters of fuel per year. To put that in perspective, commercial airlines produce about 300 million tons of fuel per year.

Construction of the industrial plant DAWN and the technical deisng and construction planning of Synhelion’s first commercial plant in Spain is being financed by CHF 22 million raised in a 2022 financing round and CHF 16 million raised in 2021. The 2022 funding round was led by existing and new investors, such as SMS Group, CEMEX, Eni, AMAG Group and SWISS. The company has also raised funds from the German Federal Ministry for Economic Affairs and Energy. The Swiss scale-up plans to raise a new round of funding in 2024.

Once the technology scales the goal is to get the production cost down to around one euro per liter of fuel within the next 10 years, Furler says.

Helping Solar-To-Liquid Fly

The first customer for the solar-to-liquid fuel from the German and Spain plants is Lufthansa Group and its subsidiary Swiss International Airlines. The aviation industry has committed to achieving net-zero flying by 2050, but notes McKinsey, the path to reaching that goal is complex. For starters there is not enough sustainable aviation fuel (SAF) available to meet demand.

“We partnered with Lufthansa to help us understand how to establish this value chain,” says Furler. “Do we produce synthetic crude oil, refine it into kerosene and then blend it with fossil fuels and make certified jet fuel or do we stop at the crude level and have it co-processed at a refinery? We need to understand what best fits the needs of the aviation industry and what is most effective and economical.”

As a new member of the World Economic Forum’s Global Innovators Community, an invitation-only group of the world’s most promising start-ups and scale-ups that are at the forefront of ethical technological and business model innovation, Synhelion is actively contributing to the Forum’s Airports of Tomorrow (AoT) initiative. As part of the WEF’s Center for Nature and Climate, AoT’s aim is to address the energy, infrastructure, and financing needs of the aviation industry’s transition to net-zero carbon emissions by 2050. AoT is investigating how SAF producers can be supported to serve rising demand and bring them together with the right partners. The overall goal of the initiative is to make sure that SAF will be available on the market in time to meet emission reduction targets. Based on the results of planned roundtables and meetings held within the AoT initiative, the Forum will publish short case studies on policy implementation that address topics like the ideal countries and regions to produce SAF and what that means for regulation and incentive creation.

Cementing A Greener Future

Synhelion’s technology also holds promise for the greening of other industries, such as cement. In August Synhelion and Cemex announced a significant milestone in their joint effort to develop fully solar-driven cement production: the scaling of their technology to industrial-viable levels. This includes the continuous production of clinker, the most energy-intensive part of cement manufacturing, using only solar heat.

At the beginning of 2022, the companies announced the first-ever successful production of solar clinker in a small-scale batch process pilot. “Advancing from that stage to production under plant-like and continuous conditions reaffirms the tremendous potential of this technology to reach industrial-scale implementation,” the two companies said in a press release. Synhelion and Cemex say they are now takin steps toward building a solar-driven industrial-scale pilot cement plant.

Clinker is produced in a rotary kiln at temperatures nearing 1’500°C. Fossil fuels are typically used to heat the kiln and are responsible for approximately 40% of direct CO2 emissions. Synhelion’s technology provides sufficient heat to produce clinker without using fossil fuels. Replacing fossil fuels entirely with solar energy would be a game-changer in Cemex’s efforts to achieve carbon neutrality by 2050, says the company. Additionally, the technology creates the conditions to separate, and therefore capture, the remaining CO2 from calcination in concentrated form without additional efforts.

The partnership between Synhelion and Cemex has recently receive recognition. The U.S. Department of Energy awarded $ 3.2 million to Solar MEAD, a joint project between Cemex, Sandia National Laboratories, and Synhelion to study the conditions to maximize heat transfer to the raw cement mix. The collaboration also received an honorable mention in the Eco-Innovator category of the Corporate Citizenship Innovation Awards sponsored by the Boston College Center for Corporate Citizenship – an organization dedicated to advancing the work of corporate social responsibility and sustainability.

Reducing Risk

Synhelion’ technology can also be applied to other industries that require high temperature process heat, such as the steel sector, but scaling up to serve the needs of multiple industries is challenging and will require investment and regulatory clarity. “We need industrial partners and investors who are willing to take risks,” says Furler.

As pressure mounts on established companies to become greener investing in clean technologies like Synhelion’s could help them reduce their own risks.

The oil and gas sector is a case in point. In transitions to net zero, oil and gas is set to become “a less profitable and riskier business over time,” says the IEA report. The report’s analysis finds that the current valuation of private oil and gas companies could fall by 25% from $6 trillion today if all national energy and climate goals are reached, and by up to 60% if the world gets on track to limit global warming to 1.5 °C.

The report finds that the oil and gas sector is well placed to scale up some crucial technologies for clean energy transitions. In fact, some 30% of the energy consumed in 2050 in a decarbonized energy system comes from technologies that could benefit from the industry’s skills and resources, including liquid biofuels.

However, this would require a step-change in how the sector allocates its financial resources. The oil and gas industry invested around $20 billion in clean energy in 2022, or roughly 2.5% of its total capital spending. The report finds that producers looking to align with the aims of the Paris Agreement would need to put 50% of their capital expenditures towards clean energy projects by 2030, on top of the investment required to reduce emissions from their own operations.

The report also notes that carbon capture, currently the linchpin of many firms’ transition strategies, cannot be used to maintain the status quo. If oil and natural gas consumption were to evolve as projected under today’s policy settings, limiting the temperature rise to 1.5 °C would require an entirely inconceivable 32 billion tonnes of carbon captured for utilisation or storage by 2050, including 23 billion tonnes via direct air capture. The amount of electricity needed to power these technologies would be greater than the entire world’s electricity demand today, says the IEA report.

Working with Synhelion would make sense for oil and gas companies because a large fraction of the investment cost in the scale-up’s plants is made up of standard oil and gas technology such as Fischer-Tropsch, compressors and gas cleaning developed over the last 100 years. “We are producing the same products (with the difference being ours is sustainable) that will serve the global oil and gas infrastructure for refining and product distribution,” says Furler. “Therefore, oil and gas should be interested to maintain the value of their infrastructure, which could be lost if the energy system changes to other energy carriers. Oil and gas can handle large projects with high CAPEX and long plan lifetime, thus would be perfectly suited to be the future owner and operators of our plants.”

Clean energy progress “will continue with or without oil and gas producers,” notes the IEA’s Birol in the organization’s annual report. “However, the journey to Net Zero emissions will be more costly, and harder to navigate, if the sector is not on board.”

To read more of The Innovator’s Energy Transition articles click here.

This article is content that would normally only be available to subscribers. Sign up for a four-week free trial to see what you have been missing.