The road to market for solar fuels

Published in 2021, updated in 2024

Our inspiration for solar fuels began with an extraordinary idea: What if it was possible to reverse combustion and generate fuel from air and sunlight? The idea worked – at first on paper, then in the lab, and finally in the field. In 2016, Synhelion was founded to bring solar fuels to market. With our pioneering solar fuel technologies, we want to create a global impact and effectively reduce CO2 emissions.

Since then, Synhelion has evolved from a startup to a successful cleantech scale-up company, that provides innovative solutions to produce sustainable fuels. In late 2022, Synhelion started to build its first industrial-scale solar fuel plant DAWN in Jülich, Germany. This plant was inaugurated in June 2024 and has been successfully producing synthetic renewable fuels since late summer 2024.

This article provides an overview of the milestones Synhelion has achieved so far in its journey to move the world toward a net-zero transportation sector and looks ahead to the next milestones we will achieve.

An outstanding track record

In 2019, we produced the world’s first drop of solar fuel under real field conditions at a mini-refinery on the roof of ETH Zurich. This solar mini-refinery marked the starting point of our scale-up journey.

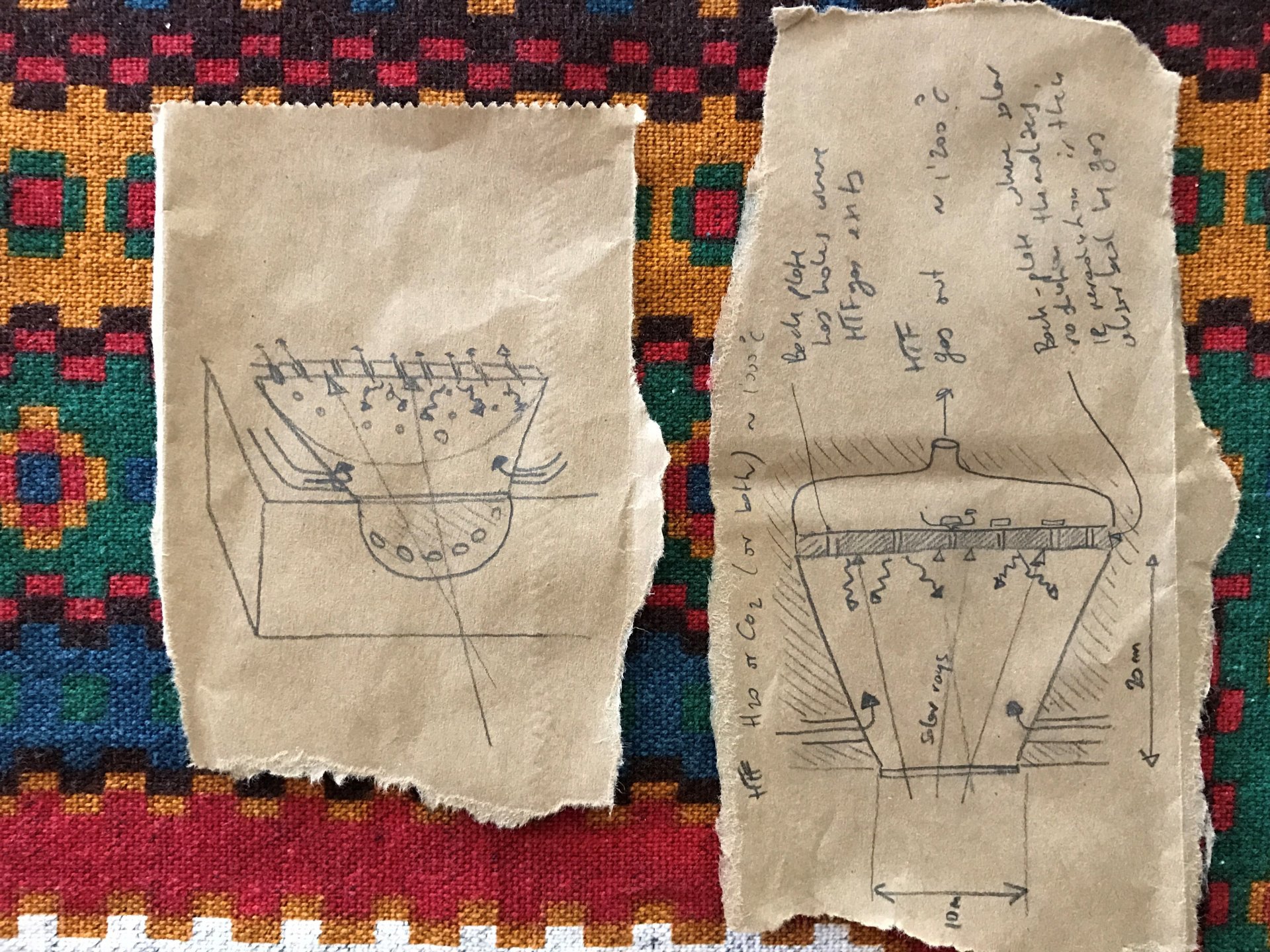

One of the challenges we had to overcome to be able to scale our technology was the necessity for extremely high-temperature process heat at 1’000 to 1’500°C, which existing solar receivers weren’t able to generate. To overcome this obstacle, our Co-CEO and Co-Founder, Dr. Gianluca Ambrosetti, invented a completely novel type of solar receiver.

A prototype of this new solar receiver was built and subsequently tested at the German Aerospace Center’s Synlight facility in March 2020. It outperformed state-of-the-art solar receivers by 550°C, marking a major breakthrough for the solar thermal industry.

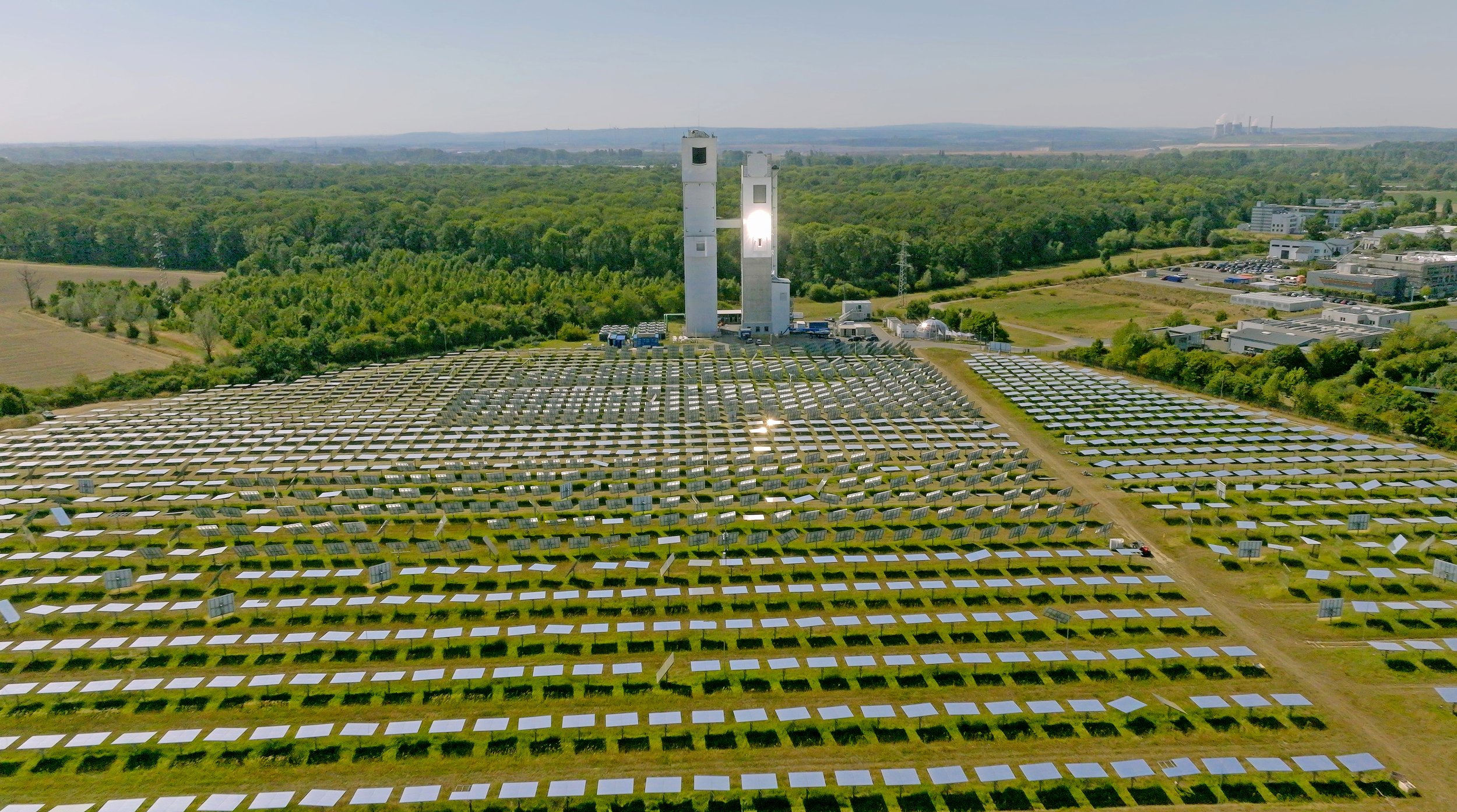

With the new 1’500°C solar receiver proven to work, we achieved a crucial step toward scaling our technology. We then continued our scale-up journey at the Solar Tower Jülich, a research facility owned by the German Aerospace Center featuring a solar tower and over 2’000 heliostats. There, we built an integrated system featuring our receiver and reactor, and in 2022, we successfully produced syngas using only solar heat as energy source. Syngas is the universal brick needed to produce any type of liquid hydrocarbon fuel, such as jet fuel, diesel, or gasoline. With the successful production of syngas on an industrial scale, the last decisive technical milestone for the industrial production of carbon-neutral solar fuels had been reached.

Approaching the dawn of industrial solar fuel production

In late 2022, Synhelion started to build plant DAWN in Jülich, Germany. Plant DAWN is the world’s first industrial-scale solar fuel production plant performing the whole Sun-to-Liquid production process from sunlight to liquid fuel. This plant was inaugurated in June 2024 and has been successfully producing synthetic renewable fuels since late summer 2024. The fuels produced at DAWN are being used for relevant showcases across the transportation sector to demonstrate the relevance of sustainable fuels to reach net-zero in the transportation sector.

Creating impact fast

We are working on scaling the production of synthetic fuels from solar energy and aim to rapidly bring them to market. Solar fuels can substantially reduce net carbon emissions compared to fossil fuels, minimizing the impact of transportation on climate change.

What is solar fuel and how does it work?

Synhelion uses solar heat to convert CO2 into sustainable synthetic fuels. We call them solar fuels. In our Sun-to-Liquid technology with concentrated solar power, which will be implemented at DAWN, we combine our four patented components, i.e. the heliostats, the receiver, the thermochemical reactor, and the thermal energy storage unit. A field of mirrors (heliostats) concentrates solar radiation onto the receiver, where it is turned into high-temperature process heat. The generated heat drives a thermochemical reactor to produce syngas, a mixture of hydrogen and carbon monoxide. The syngas is then processed by standard gas-to-liquids technology into liquid fuels such as gasoline, diesel, or jet fuel. Solar fuel production runs 24/7 thanks to integrated thermal energy storage. Synhelion’s solar fuels can directly replace fossil fuels and are fully compatible with conventional internal combustion engines and jet turbines and reduce net carbon emissions by more than 80%.

This approach aligns with the goals set in the Paris Agreement and acknowledges the need for cost-effective solutions that drastically reduce CO2 emissions early on in this decade.

Joining forces to bring solar fuels to market

Reducing CO2 emissions is the greatest challenge of our time. We pursue a collaborative approach with leading global industrial partners and top-tier research labs to implement our technology on a global scale. Our partners include Eni, Cemex, Lufthansa Group, Swiss International Air Lines, SMS group, Wood, AMAG Group, and Zurich Airport. End customers show great commitment for our products. SWISS will be the first airline in the world to use our solar fuels.

Subscribe to our newsletter to hear from us as we reach our milestones. Talk to us if you want to be part of our journey as an investor or partner.